Laser engraving

If you've ever admired a beautifully engraved wooden keepsake or a sleek metal trophy with a crisp design, chances are you were looking at a product customized with laser engraving.

This versatile yet precise technique has become increasingly popular for creating unique, personalized products.

Let’s explore laser engraving’s advantages, limitations, and the products this customization method suits the best.

What is laser engraving?

Laser engraving is a process that uses a high-powered laser beam to create precise, deep cuts directly into the surface of a material.

As the laser beam penetrates the material, it vaporizes a portion of the surface, resulting in a cavity that forms your desired design. The depth of the engraving can be adjusted by controlling the power and duration of the laser pulse.

Laser engraving is similar to laser marking, but there's a key difference: laser engraving involves deeper cuts in the material (hence “engraving” rather than “marking”).

How does laser engraving work?

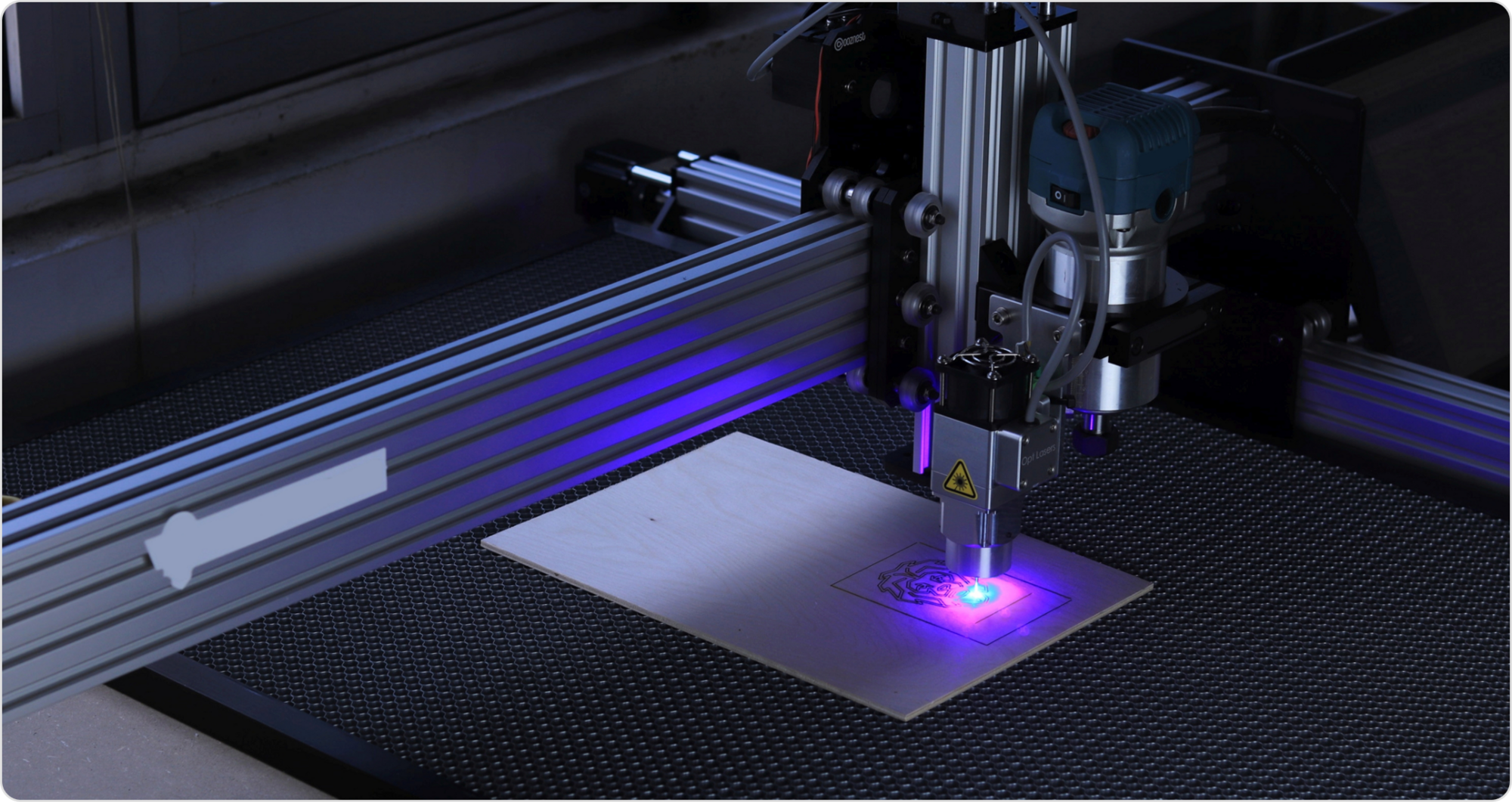

First, you’ll need a digital file of your design. The file is then loaded into the laser engraving machine, translating the design into movements for the laser beam.

Your chosen compatible material is placed into the machine, and the laser beam is focused onto its surface.

As the beam moves across the material, it removes a tiny layer of the surface, creating deep, crisp lines that form your design.

The laser's intensity and speed can be adjusted to control the depth and detail of the engraving.

Pros and cons of laser engraving

Probably the greatest advantage of laser engraving is its incredible precision.

The laser beam can create incredibly intricate designs with clean, sharp edges – ideal for reproducing complex patterns, detailed illustrations, and small text.

Here are some of the key benefits:

- Precision: Laser engraving can produce highly detailed designs with clean, crisp lines.

- Permanence: Engraved designs are durable and long-lasting, as they become a permanent part of the material's surface.

- Versatility: Laser engraving works on a wide range of hard materials, including metal, glass, wood, leather, and some plastics.

However, as always, there are a few drawbacks to consider:

- No color: Laser engraving produces single-color designs. The engraved areas will be the color of the material beneath the surface.

- Material limitations: While laser engraving works on many hard materials, it's not suitable for all surfaces, particularly very thin or delicate materials that the laser could damage.

What kind of designs work best for laser engraving?

Laser engraving is an excellent choice for designs that:

- Feature complex details and fine lines

- Incorporate small text or numbers

- Require a high level of precision and clarity

- Work well as single-color graphics

Laser engraving is ideal for smaller, more detailed designs, from company logos and branding to personalized text and patterns.

What products are most suitable for laser engraving?

Laser engraving works best on products made from hard, durable materials. Some of the most popular options include:

- Metal drinkware and flasks

- Glass awards and plaques

- Wooden cutting boards and boxes

- Leather journals and wallets

- Acrylic keychains and tags

When choosing a product suitable for this technique, consider the material's thickness, hardness, and ability to withstand the laser's heat.

FAQs about laser engraving

1. Can you laser engrave glass?

Yes, you can laser engrave glass using specialized laser engraving machines designed to work with this delicate material. However, the process requires careful control of the laser's power and speed to avoid cracking or shattering the glass.

2. Can you laser engrave leather?

Yes, you can laser engrave leather to create unique, personalized designs on products like wallets, journals, and keychains. The laser engraving process creates a permanent, precise design that will not fade or wear off over time.

3. Can you laser engrave plastic?

Some plastics can be laser-engraved, depending on their composition and thickness. Due to its durability, acrylic is one example of a plastic that is suitable for laser engraving.

As a warning: some plastics may melt or release harmful fumes when exposed to the laser's heat, so choosing the right material is essential.

Bring your designs to life with laser engraving

Overall, laser engraving is a powerful tool for creating precise, permanent designs on a variety of hard surfaces.

With its ability to reproduce excellent detail, this versatile technique offers endless opportunities for customization.

Ready to engrave your design onto a special product? Browse our catalog to start designing your very own laser-engraved creation!