2D flat embroidery

If you've ever owned a piece of clothing with embroidery, like a monogrammed shirt or a logo cap, there’s a good chance it was created using flat embroidery.

Flat embroidery is a tried-and-true technique for adding visual details to fabric. It's durable, flexible, and effective for a wide variety of designs.

In this guide, we'll explore how flat embroidery works, its unique advantages, and our top tips for creating flat embroidery designs that truly stand out.

By the time you're finished reading, you'll be ready to dream up your own custom flat embroidery projects and make them a reality.

What is flat embroidery?

Flat embroidery, also known as 2D embroidery, is a traditional embroidery technique where designs are stitched directly onto fabric using thread. The threads lay flat against the material, creating a smooth, slightly raised texture that doesn't protrude from the surface.

The result is a clean, crisp design with precise lines and details. Flat embroidery can accurately reproduce relatively complex patterns and images, making it an incredibly versatile technique suitable for a wide range of design styles.

It’s particularly effective for hats, patches, and clothing made out of heavier textiles, such as heavyweight t-shirts and jean jackets.

How is flat embroidery done?

Now that you know what flat embroidery is, let's take a look at how the process works.

Here’s a step-by-step breakdown to help you understand how your designs are brought to life using this technique:

- Digitizing the design: In the first step, we convert your artwork into a digital embroidery file. This involves breaking down your design into individual stitches and thread colors that the embroidery machine can understand.

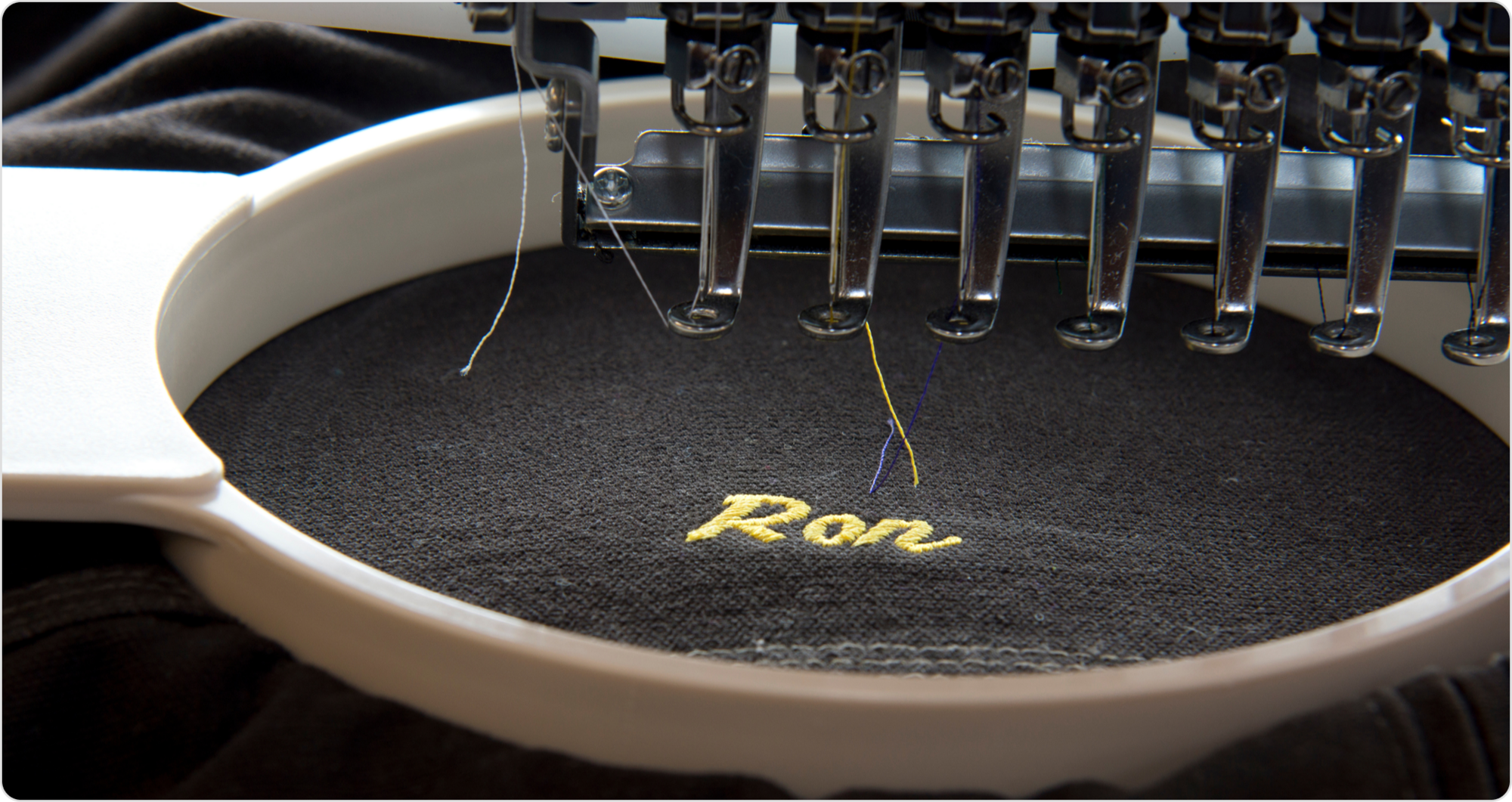

- Preparing the fabric: Next, the fabric is hooped tightly to keep it flat and stable during the embroidery process. A stabilizer may be added to the back of the fabric to provide extra support, ensuring your design looks its best.

- Stitching the design: The hooped fabric is then loaded onto the embroidery machine, which stitches your digitized design onto the material with precision. The machine automatically changes thread colors as needed to reproduce your original artwork accurately.

- Finishing touches: Once the embroidery is complete, any loose threads are carefully trimmed away. Your item then goes through a rigorous quality control process, which may include pressing or steaming the item to ensure the design lays flat and looks perfect.

The length of time the flat embroidery process takes will vary depending on the size and complexity of your design. The result is a beautifully embroidered item that's built to last.

Flat embroidery vs. 3D puff embroidery

While flat embroidery is one of the most popular techniques for customizing apparel and accessories, it's not the only option out there.

Another popular method is 3D puff embroidery, which involves placing foam underneath the embroidery stitches to create a raised, three-dimensional effect. As the design is stitched, the foam is compressed by the thread, making the design appear to "pop" off the fabric.

3D puff embroidery is often used on the same types of items as flat embroidery, such as hats, jackets, bags, and other apparel. So, how do these two techniques compare? Let's take a look:

As you can see, each technique has its own unique advantages. Flat embroidery is more versatile and budget-friendly, while 3D puff has a greater visual impact but is more limited in terms of design complexity and fabric choices.

What designs work best with flat embroidery?

One of flat embroidery's biggest advantages is its ability to reproduce relatively complex, detailed designs.

That said, some types of designs are particularly well-suited to flat embroidery, such as:

- Simple logos with bold lines

- Illustrations and graphics with defined outlines and borders

- Lettering, especially in block or sans-serif fonts

- Geometric patterns and shapes

Designs with gradients, photorealistic details, or super-thin lines may need to be simplified or adjusted for embroidery.

In general, it’s best to avoid:

- Super-thin lines (for both text and images)

- Ultra-fine, intricate details (i.e., shading or textures)

- Small text

Following these guidelines will ensure that your design will look its best!

The best products for flat embroidery

Another major selling point of flat embroidery is that it can be applied to virtually any fabric item. From hats and shirts to bags and beyond, if it's made of fabric, it can likely be embroidered using this technique.

Some of the most popular products for custom flat embroidery include:

- Hats and caps

- Polos and button-down shirts

- Hoodies and sweatshirts

- Tote bags and backpacks

- Aprons and kitchen textiles

- Towels and blankets

- Patches and appliques

When choosing a product for flat embroidery, it’s important to opt for items made from tightly woven, medium-weight fabrics for the best results. Very thin, stretchy, or heavily textured materials are usually not suitable for embroidery.

FAQs about 2D flat embroidery

Interested in using 2D flat embroidery for your next custom product through Wayo?

Here’s what you need to know if you’re placing a catalog product order.

1. Are there any color limitations for 2D flat embroidery?

At Wayo, we can support up to 5 solid colors in a single design.

2. What happens if my design has many fine details?

If your design is very complex or intricate, it may be best to consider a different customization method, such as heat transfer. This is because embroidery utilizes a stitch array technique, meaning that each design element or color must be a certain minimum width to be properly produced.

3. Can 2D flat embroidery be combined with 3D puff embroidery?

Yes, you can combine flat embroidery with 3D puff embroidery.

4. Do these restrictions apply to fully custom products?

It depends on your request! Our goal is to help you turn your vision into a reality, and we will do our best to help you source and create the perfect product!

Submit a fully custom request* if you are interested in using 2D flat embroidery for your next 100% custom project. In general, your project is more likely to be possible if:

- Your desired product is crafted from a sturdier, medium- or heavy-weight material

- Your desired design isn’t too detailed, ranging from low- to medium- complexity

- You are open to considering other customization methods

*Minimum order quantity for fully custom requests typically start at 1,000 units.