UV printing

UV printing is a printing process that uses specially formulated inks that instantly cure and harden when they’re exposed to UV light. UV printing is popular because it creates sharp prints with vibrant color. It can also be used on a huge range of materials. As well as these main benefits, UV printing also offers other advantages over alternative printing methods.

You can use UV printing to print personalized images, text, or even texture designs on your own custom products. You can personalize almost any product with UV printing

In this guide, we'll explain how UV printing works, what materials and products it can be used on, and why it might be a great printing choice for your products.

What is UV printing?

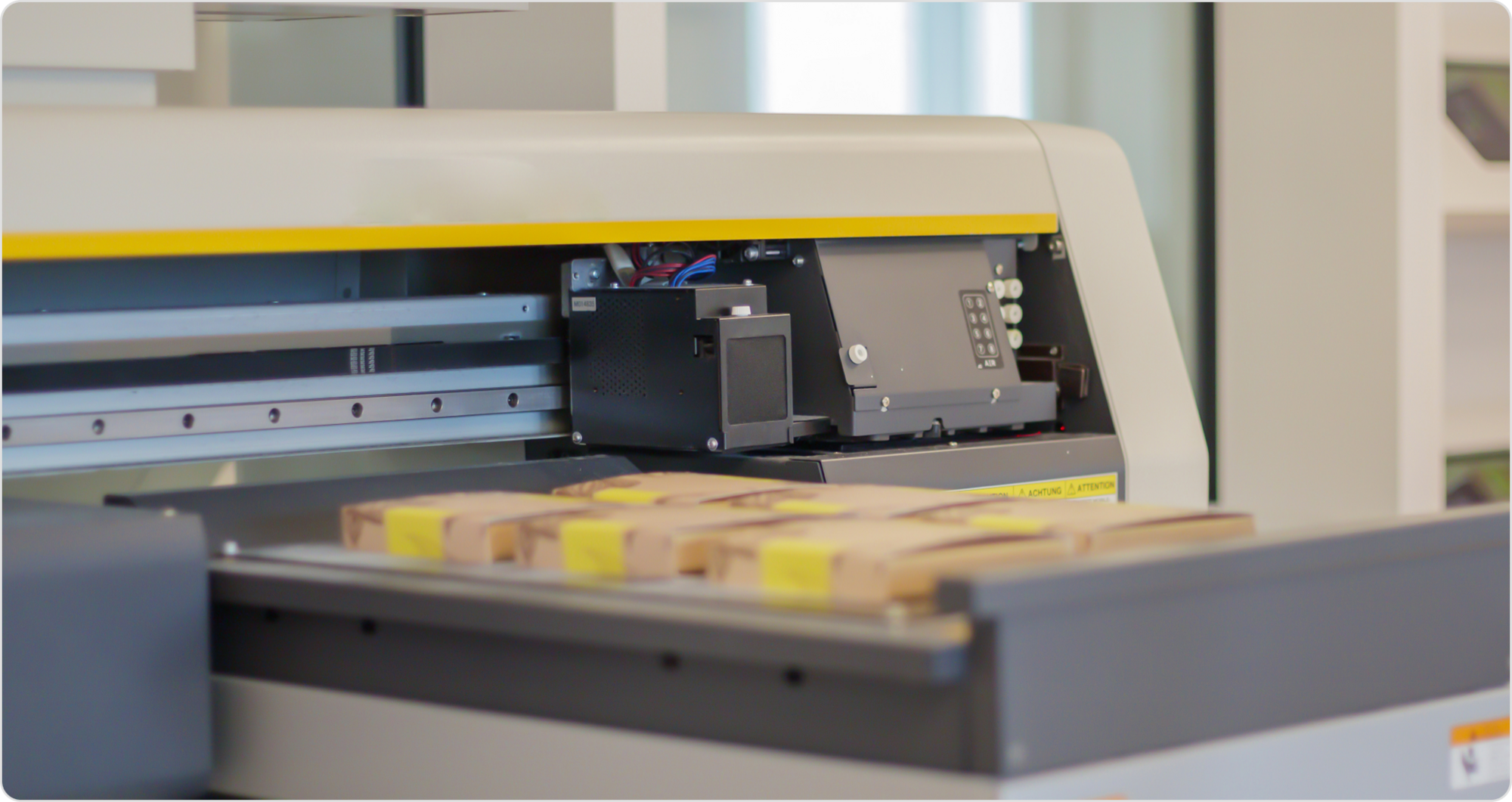

Ultraviolet (UV) printing is a unique digital printing process in which specially designed UV curing inks and printers with ultraviolet lights are used to create high-quality, fast-drying prints.

UV printing can be used for simple designs as well as to create effects such as textures or gloss.

How does UV printing work?

The UV printing process is simple. Here's a step-by-step breakdown:

- UV printers with specialist print heads print UV curing inks directly onto the object.

- An LED UV light installed within the printer follows behind and instantly cures the ink.

- The curing of the ink happens so rapidly that the ink dots do not have any time to spread, resulting in a high resolution print.

UV printed surfaces do not need time to dry or cool down, making the entire process very fast.

What materials does UV printing work on?

One of the main benefits of UV printing is that it’s compatible with a very wide range of materials.

Fast ink curing speeds mean that inks are less prone to reacting with materials or spreading before they harden. LED UV lights also operate at low temperatures, making the process compatible with materials that are vulnerable to high temperatures.

Here are some of the materials UV printing can be used on:

- Paper and cardboard

- Metal

- Glass

- Plastics

- Tiles

- Foil

- Foam

- Textiles

UV printing on unusually shaped objects

Another benefit of UV printing is that it can also be used on materials that are not flat.

While flatbed UV printers are limited to flat materials, there are specially designed UV printers that can print on objects of varied shapes. Using these printers, cylindrical objects like water bottles or wine bottles, as well as objects of other unusual shapes, can be UV printed.

Another alternative is to use UV DTF printing, in which a flatbed UV printer is used to print onto a film that is used to transfer the design onto the object.

Advantages and disadvantages of UV printing

Here's a complete breakdown of the advantages and disadvantages of UV printing compared to other traditional printing methods.

Advantages of UV printing

- High-quality prints - UV printers create sharp prints with vibrant colors and a high level of detail.

- Fast production speeds - Instant ink drying leads to a fast overall printing process.

- Compatible with a wide variety of materials - UV printing works very well on a huge range of materials.

- More environmentally friendly - Inks used in the UV printing process do not contain volatile organic compounds. Few toxic fumes or other pollutants are also created during printing.

- Durable finishes - UV ink finishes are scratch, impact, and fade resistant.

Disadvantages of UV printing

- Limited color options - Although UV curing inks produce vibrant colors, there is in fact a slightly limited color range. Color matching or precise color choices may not always be possible.

- Finish incompatibility - Some extra material finishing processes don’t work on UV printed surfaces.

- Material incompatibility - UV printing is incompatible with some materials.

- May be unsuitable to bendable objects - UV curing inks may not perform well on some materials that will bend or flex.

- Limited print area - UV printers might print on a smaller area than other printer types.

Is UV printing better than sublimation printing?

Sublimation printing is a printing process that, like UV printing, is known for producing high-quality, durable prints. Sublimation can also be used on cylindrical or otherwise awkwardly shaped objects.

With sublimation, special dyes are first printed on paper. The paper is then placed on the object, and heat and pressure are then applied to it. The dye sublimates (turns to gas) and is printed on the material.

Sublimation can be used to produce similar results to UV printers, and it works perfectly for lots of printing jobs. However, UV printing is generally:

- Faster

- Cheaper

- More environmentally friendly

- Compatible with a wider range of materials.

What kinds of designs are suitable for UV printing?

UV printing can be used for images, photographs, logos, and text, as well as for 3D textures and other effects.

UV printers are capable of printing very intricate designs. UV inks also cure instantly, meaning that less dot spread and ink absorption happens. This makes it possible to create very precise and detailed designs.

You can also use vibrant colors, and it’s even possible to produce gloss, textures, or other effects with UV printing technology.

What kinds of products can UV printing be used on?

Because UV printing can be used on a wide range of materials and on objects of unusual shapes, it can be used on almost any product. You can use UV printing to create sharp and detailed designs on almost anything you want. The prints will also be hardwearing and resistant to fading.

As we mentioned earlier, UV printing can be used on paper and cardboard, metal, glass, plastic, textiles, and other materials as well.

Here are some examples of products that can be UV printed:

- Electronic gadgets like power banks

- Cellphone, laptop, and tablet cases

- Glassware, such as wine bottles and glasses

- Custom-designed laptop sleeves

- Stainless steel coffee mugs or water bottles

- Office stationery and goods like pens, mouse pads, desk fans, or notebooks

- Ceramic plates, bowls, mugs, or tiles